他の要素と共に、同期コンデンサーは多くの電力システムにおいて重要な要素です。レギュレーターは、システム内を流れている電気の電圧と電流を制御します。このような制御は重要であり、家庭や企業への電力供給を遮断する可能性のある停電などを回避できます。しかし、これらは運転中に大量の熱を発生させます。過熱すると、部品が損傷したり効率が低下したりします。それが水素冷却の有用性です。

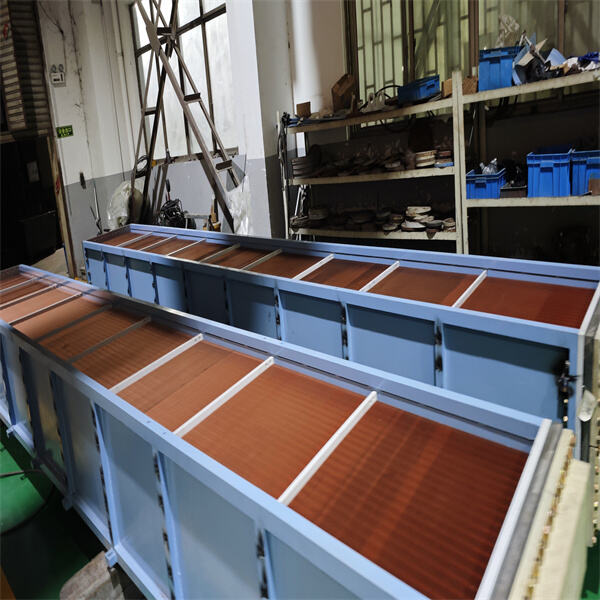

水素冷却は、現代的な解決策として世界の大半の電力会社で高い需要があります。当社はこの技術のリーダーとして、最先端のソリューションを通じてお客様の電力システムの進化を支援できることを誇りに思います。 同期コンデンサ用水素冷却器 これは、私たちが考えるに、システムが動作する方法において大きなゲームチェンジャーになる可能性があります。

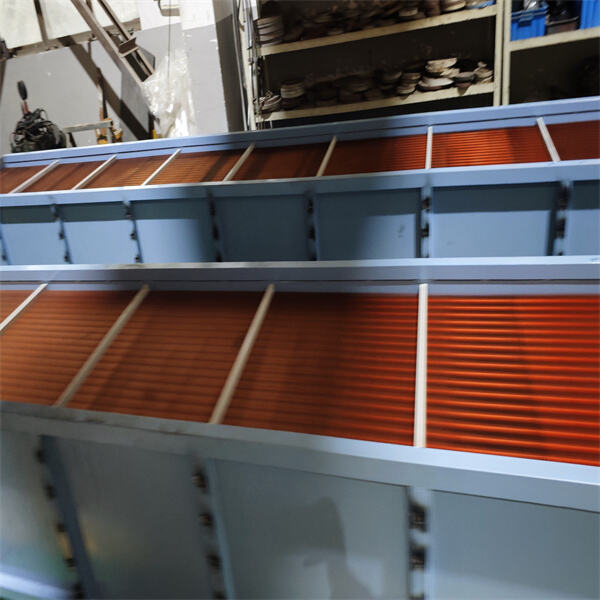

水素冷却は非常に効率的です。水素(通常の空気や水冷却と比較して)は、同じスペース内ではるかに多くの熱を吸収できます。これは、冷却に必要な水素が少なくなることを意味します。また、低コストでモジュラー構造であり、有毒成分を含まないため、保管や輸送が簡単で、電力会社のコストを削減します。

私たちは、リッチでの貢献を目指し、異なる方法で同期コンデンサーを水素で冷却する世界へ向けて進んでいます。材料科学の進歩を通じて、リッチを設計しています。 同期コンデンサー用の水素クーラー これは、これまでになく高性能で信頼性が高く、さらに低コストを実現します。これにより、電力会社は機能が向上しただけでなく、使用がよりシンプルな新しい技術を利用できるようになります。

また、モジュラーでスケーラブルな水素冷却装置も製造しています。これにより、各顧客の固有の要件に合わせてカスタマイズできます。さらに、ほぼメンテナンスが不要で、操作が非常に簡単であるため、ダウンタイムが非常に少なくなります。これにより、電力会社は費用を節約でき、インフラストラクチャの安定稼働を維持できます。

水素冷却は、同期コンデンサーを使用してシステムの性能と信頼性を向上させるために電力会社が活用できる技術です。水素冷却式コンデンサーはより高い冷却能力を持ち、そのためより高い出力レベルで動作できます。追加の冷却能力により、需要の高い時期におけるバックアップ発電機やその他の緊急措置の必要性が軽減されます。

最後に、決して重要性を失わない点として、水素冷却は同期コンデンサーの寿命を延ばすための再生可能ソリューションです。水素を燃焼させることで、温室効果ガスやその他の有害な排気ガスが生成されません。自体としては、水素はクリーンで再生可能な燃料です。リッチな 水素冷却装置(同期コンデンサー用) 電力会社は、この変化において重要な役割を果たし、世界をより持続可能な未来へと導く手助けをすることができます。

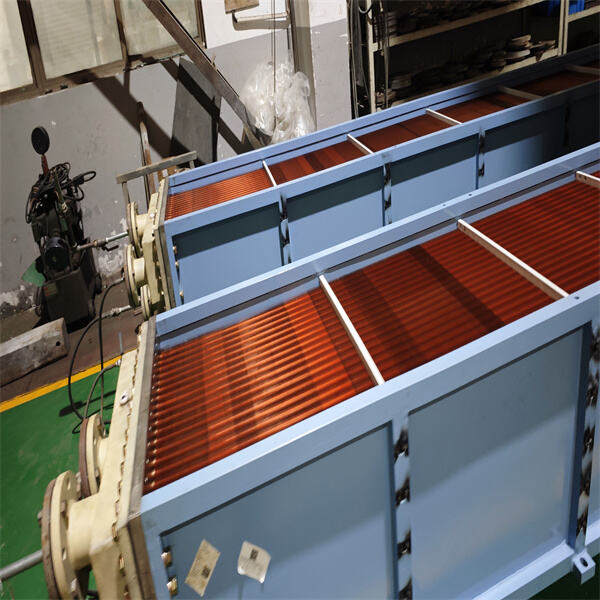

電力システム用の同期コンデンサの水素冷却装置は、顧客にワンストップソリューションを提供できるだけでなく、プロフェッショナルなスタッフによる製品のライフサイクル全体のサービスも提供します。技術的な事前販売で顧客に設計支援やシステム協力サービスを提供します。また、非常にスキルのある技術者、管理者、生産スタッフが手順管理、設置支援、技術的なトレーニング、ならびに試運転と検査を提供します。アフターサービスには、専門のサービスチームが含まれ、アフター品質問題分析の迅速な対応や現地での品質問題の解決、さらにはシステム設計の長期的改善も行います。

上海リッチM&E製造有限公司は、1998年に設立され、20年間営業を続けています。以来、電力システム用の同期コンデンサの水素冷却装置の製造から、クーラー、電力収集リング、水処理装置、鉄道保守、オンラインモニタリングのためのインテリジェント診断、その他のシステムや製品に至るまで、幅広い範囲の製品を取り扱っています。

営業部門には経験豊富な技術チームが配置されており、電力システム用同期コンデンサの水素冷却装置の管理において、設置時のプロセス制御や技術指導、さらに試運転と検査を提供します。アフターサービスでは、特別なチームがアフター問題分析、迅速な対応と現場での問題解決、そして製品システム設計に関する長期的な改善を行います。

同社は常に技術と電力システム用同期コンデンサーの水素冷却装置を使用し、そのコア競争力を強化しています。さらに、研究開発費は年間売上の5%を占めています。同時に、同社は高度な技術を持ち、安定した、現実的で革新的な優秀な研究開発人材のチームを雇用しており、エンジニアや技術者の割合は20%を超えています。

著作権 © 上海リッチM&E製造株式会社。全著作権所有。 - プライバシーポリシー