技術は世界で重要な役割を果たしています。それは私たちにとって非常に簡単で便利なものになっています。この記事では、一種の冷却システムについて議論します。これらのバイパスクーラーは、同期コンペンセイターと呼ばれる機械に使用されます。

リッチ同期コンペンセイターとは何ですか? 同期コンペンセイターは、電力網における電圧の安定性を保つために重要な役割を果たします。電力網は消費者や家庭への電力供給を意味します。しかし、大きな電圧変動はあなたの機器を壊したり、電圧低下(ブラウンアウト)を引き起こしたりすることがあります。したがって、これらの停電は誰にとっても厄介です。これが理由で 同期コンペンセイター は重要であり、良好な状態を維持することは極めて重要です。水素エネルギーの最良の利用法は冷却材としての使用であり、それが得意としています。

水素冷却を使用して冷却される同期コンデンサはかなりの印象を与えます。なぜなら、水素はそのような部品を冷却するための最も効率的な方法だからです。これにより、機械の寿命が保たれ、より良い機能が確保されます。では、水素冷却はどのように機能するのでしょうか? 機械は空気や水ではなく、水素ガスで冷却されます。ここで水素が登場します — それは熱を素早く取り除くのに非常に優れています。これにより、同期コンデンサから熱を空気や水よりもずっと速く除去することができます。機械が適切に動作するために温度を維持する必要があります。

そして、あなたは使用するものがあなたの時間予想を超えたときにそれを愛さないですか?似たようなコンセプトが同期コンペンセイターに適用されます。リッチ水素冷却は、長い期間においてあなたの同期コンペンセイターによく機能します。それはつまり、あなたがそれの修理や交換についてあまり考えなくて済むということであり、長期的にお金を節約できます。あなたが推測する通り、それがより長期間持つので、修理部門への負担が軽減され、突然壊れるという心配からも解放されます。

水素冷却は、同期コンデンサの寿命を延ばすだけでなく、その性能も向上させます。これらの機械は、より多くの電力を処理できる一方で、より多くの熱を発生させますが、水素冷却システムがそれをサポートします。これは、過熱により機械が損傷する可能性があり、熱は効率を低下させるため重要です。さらに、水素冷却の更新は数十年にわたる停止時間、つまりアイドル時間を短縮します。アイドル時間が長すぎると、長期的に機械に悪影響を与える可能性があります。リッチを使用することも有効です。 発電機用水素冷却システム 同期コンデンサが追加の運転中断なしにより長い期間効率的に動作できるようになります。

同期コンペンセイターは信頼性が求められます。停電は家庭や企業にとって非常に迷惑なものです。このような状況では、同期コンペンセイターは正常に機能し、安全に動作する必要があります。この目標は水素を使った冷却によって達成できます。これは環境に優しいことが証明されている、安全で効率的な同期コンペンセイターの冷却方法です。冷却剤としての水素は無毒のガスであり、他の冷却方法とは異なり安全に使用できます。それは非毒性であり、有害な化学物質で空気や水を汚染することはありません。

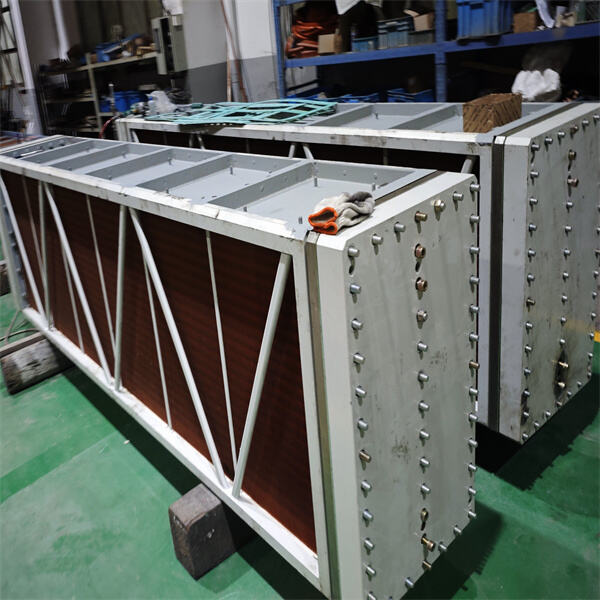

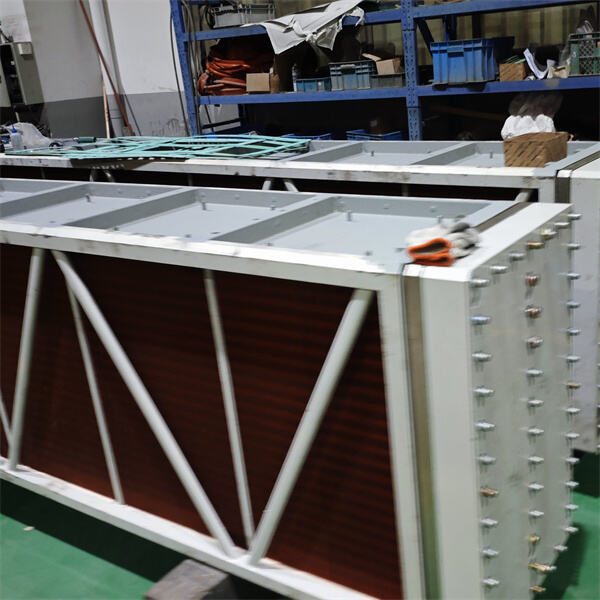

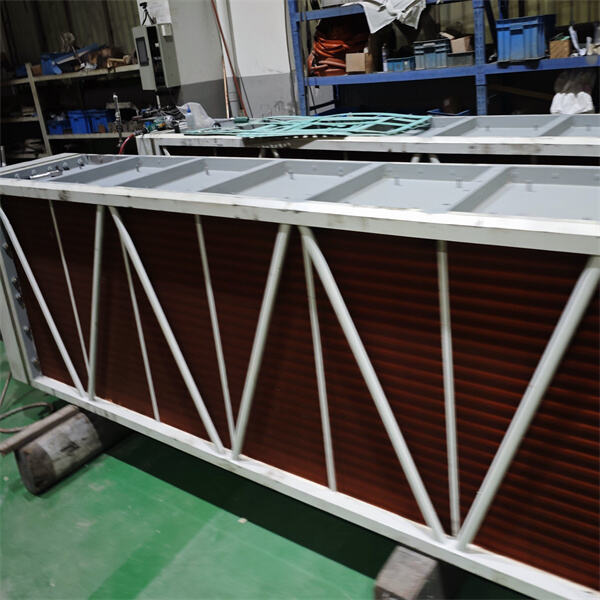

何よりも、水素クーラーはあなたの同期コンペンセイターを長期間より効果的かつ効率的に動作させます。私たちは給湯発電機用の水素クーラーの供給において世界をリードしています。彼らが提供する評判の水素クーラーは、さまざまな産業における多くの民間企業に人気のある選択肢となっています。これらは 水素冷却器 個々の顧客の要件に特化しています。その構造において堅牢な材料が使用されているため、長期間持続し、維持コストも高すぎません。

上海Rich M&E製造有限公司は1998年に設立されました。20年間の運営を通じて、同社はあらゆる種類の同期コンデンサ用水素冷却装置、パワーコレクションリング、水処理装置、鉄道メンテナンス、オンライン監視、インテリジェント診断、その他の製品やシステムの研究開発、生産、サービスおよびサポートを行っています。同社の製品は、発電所、鉄道、重工業、その他のさまざまな分野で広く使用されています。

同社は常に同期コンペンセーター用の水素冷却装置と科学的イノベーションに取り組み、そのコア競争力を高めています。研究開発費は年間売上の5%を占めています。また、会社には高度なスキルを持ち、専門的で創造的かつ実践的な研究開発人材のチームも存在します。技術者およびエンジニアリングスタッフは全体の20%以上を占めています。

同期コンペンセーター用の水素冷却装置の販売チームは、技術的な生産と管理を行い、プロセス制御、設置指導、技術指導、試運転、検査を行います。アフターサービスの販売サービスには統合されたチームがおり、販売後の問題に対応し、迅速な現場での対処や問題解決、さらには製品システム設計の長期的な改善を行っています。

同期コンデンサ用の水素冷却装置には、技術的な生産と管理を行う経験豊富なチームがおり、プロセス制御や設置指導、試運転および検査の技術指導を確実に行います。アフターサービスには、特に問題の後処理分析、迅速な介入およびウェブサイト上の問題解決、さらにはシステム設計の長期的改善が含まれます。

著作権 © 上海リッチM&E製造株式会社。全著作権所有。 - プライバシーポリシー