高電流スリップリングの利点

高電流スリップリングまたはRich 回転用スリップリング は非常に有益です。なぜなら、これらは移動する物体から静止した物体へ電力を継続的に伝達できるため、ワイヤーが絡まって故障する心配がありません。また、非常に低い抵抗を持つため、効率的で一貫性のある動作が可能です。高電流スリップリングはさらに信頼性の向上と寿命の延長も提供します。

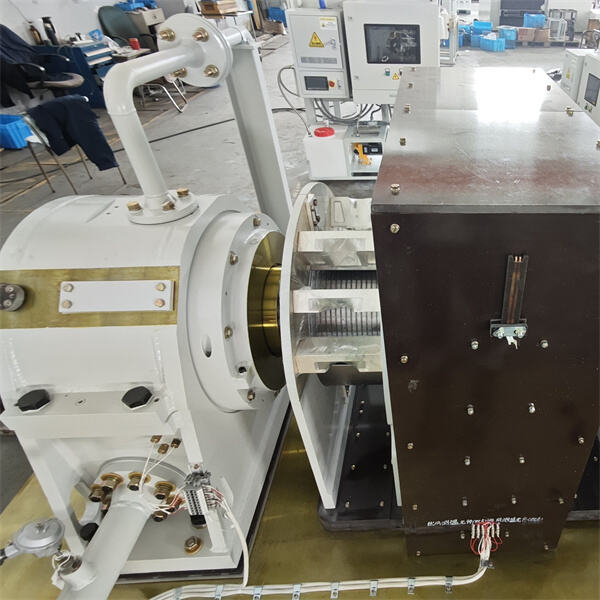

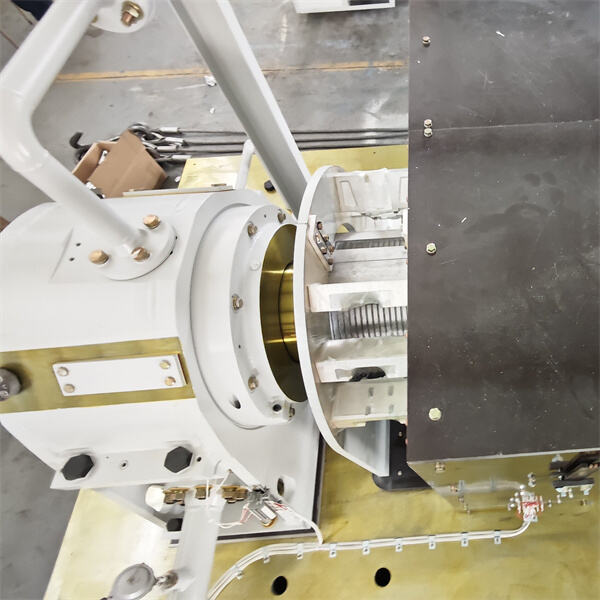

革新は高電流スリップリング技術の核心にあります。最新の技術は安全性を考慮して設計されており、最新モデルは機器や操作者への追加保護を提供するために再構成されています。リッチ 発電機のスリップリング は、短絡や過負荷などの危険な故障に対する安全装置が装備されています。

リッチ社の高出力スリップリングは、航空宇宙、海洋、軍事、発電、製造業を含むさまざまな産業で使用されています。これらは、回転ユニットに電流を送受信するために使用されます。このようなスリップリングは、風力タービンなど、連続的に回転しながら安定した電力供給が必要な設備にとって不可欠です。

リッチの高出力スリップリングを使用する 高電流スリップリング ことは複雑ではありません。これらはシンプルで効果的な設計になっています。まず、スリップリングに適切な電源端子と接続部があることを確認し、電気の伝送を可能にします。次に、スリップリングを電気の流れが必要な設備に接続します。最後に、電気ショックや露出からの適切な絶縁があることを確認します。

高電流スリップリングについては、完全なサービスが提供されています。これには、Richによるスリップリングのテストやその他の多くのチェックが含まれ、正常に機能し動作していることを確認します。トラブルシューティングやメンテナンスも提供され、高電流スリップリングの寿命を延ばします。

営業部門には高出力スリップリングの技術、管理、生産スタッフがおり、プロセス制御や技術指導、据え付け、試運転、検査を行います。アフターサービスには、別途責任チームがあり、アフター問題の分析、迅速な対応、現場での問題解決に加えて、システム設計の長期的な改善を行います。

この企業は常に高出力スリップリングと科学的進歩を追求し、そのコアコンピタンスを向上させています。年間の研究開発費は売上の5%を占めます。また、企業には専門的で、質の高い、革新的かつ実践的な研究開発人材が揃っており、エンジニアリングおよび技術スタッフは全体の20%以上を占めています。

高電流スリップリングは、間違いなく顧客にワンストップのシステムとフルサービスのライフサイクルを提供することができます。技術専門家のプレセールススタッフが顧客に設計とシステム協力システムを提供します。営業には、プロセス制御、インストール支援、そして確実に技術的な据え付けと検査を行うための専門的な技術者、管理者、生産者のチームがいます。アフターサービスでは、販売後の品質問題を分析し、迅速な対応と現場の品質問題の管理を行い、さらに長期的な設計改善も行っています。

上海リッチM&E製造有限公司は1998年に設立されました。20年間の運営を経て、現在は各种クーラー、電力収集リング装置、水処理装置、鉄道保守、オンライン監視、インテリジェント診断などの製品やシステムの研究開発、生産、サービスを提供しています。同社の製品は、発電所、鉄道、重化学工業など様々な分野で広く使用されています。

著作権 © 上海リッチM&E製造株式会社。全著作権所有。 - プライバシーポリシー