フィンファン熱交換器は、産業におけるさまざまな生産プロセスでガスや液体物質を冷却するための特殊な機械です。私たちは液体やガスを冷却する際に頻繁に熱移動のプロセスを行い、それは熱の移動プロセスの中で最も重要なステップです。これは、フィンファン熱交換器が動作する際の原理であり、比較的温度の高い液体またはガス状の流体から熱をより冷たい媒体へと除去します。これにより、すべてのプロセスが滑らかかつ安全に進行することを確実にすることができます。

フィンファン熱交換器は、多くの産業で非常に重要な役割を果たしています。それは、液体やガスをコスト効果的にかつ賢く冷却する優れた方法を提供します。フィンに取り付けられた換気扇は、新鮮な空気を吹き込み、熱を排出します。このRich フィンファン熱交換器 は、工場や発電所などでの多くのアプリケーションにおいて、熱い液体やガスを冷却するために非常に効果的です。これにより、産業で使用されるすべての機器が正常に動作し、必要な温度が維持されます。

例えば、フィンファン熱交換器は、天然ガスやプロパン、ブタンなどのガスを冷却するために、ガス処理プラントで使用されます。これらのガスはプラントに到達し、そこできれいにされて別の形に変換され、使用可能な状態になります。処理が完了すると、それらはRich 空気フィン熱交換器 プラントのさまざまなセクションに配分される前に冷却するために使用されます。これは非常に重要です因为她は極めて高温である可能性があり、処理システムが正常に機能するにはその温度が必要だからです。これらのガスは温かい状態では安全に取り扱うことができないので、冷却プロセスが必要です。

発電所でもフィンファン熱交換器が使用されています。これらはボイラー(蒸気を生成する大きな機械)で作られた蒸気を冷却します。この蒸気はタービンを通りますが、これは電力を生成するためのツールです。タービンから出る蒸気は非常に高い温度であり、再びボイラーに戻されて蒸気に戻される前に冷却する必要があります。フィンファン熱交換器により、迅速かつ効率的な冷却が可能となり、これにより発電所はエネルギーをより効果的に保存し、持続可能に運営できるようになります。実際、これにより彼らは資源を無駄にすることなく、より効率的に電力を生成することができます。

沖合の石油・ガス産業でもフィンファン熱交換器が使用されています。沖合プラットフォームは、原油と天然ガスの海洋底沈殿物を回収し、これらの資源はパイプラインを通じて陸上基地に送られます。しかし、油とガスは安全に流れ出す前に冷却する必要があります。 フィン式熱交換器 ここでリッチ(Rich)が役立ちます。また、輸送プロセスを避けるために、パイプラインを通じて伝送する前に油とガスを冷却します。さらに、これらのフィンファン熱交換器は、石油採取に使用される海水も冷却できるため、二重目的のツールです。

この企業は顧客向けにフィンファン熱交換機の据え付け方法を提供し、製品のライフサイクル全体にわたるサービスを展開しています。技術専門家によるプロの営業前スタッフが、顧客に設計と開発サービス、およびシステム協力サービスを提供します。営業部門には技術者、管理者、生産担当者が揃っており、据付管理、プロセス管理、技術的なトレーニングや試運転、検査も行っています。サービス部門は、専門チームで構成され、販売後の品質問題の迅速な対応やウェブサイト上の問題管理を行い、システム設計の長期的改善にも取り組んでいます。

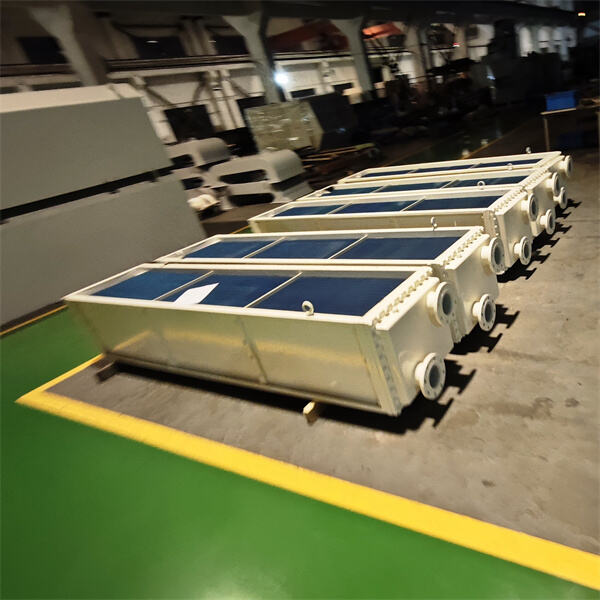

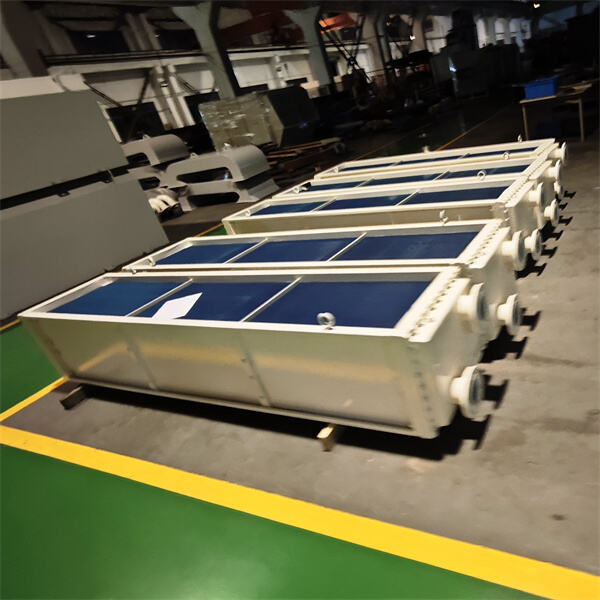

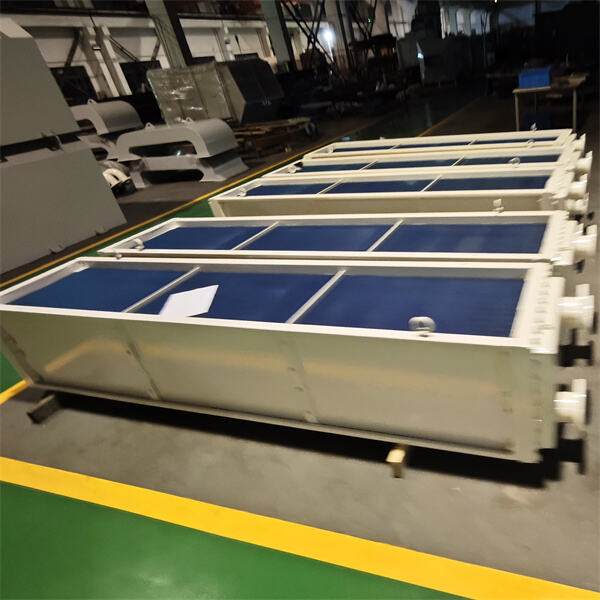

上海リッチM&E製造有限公司は1998年に設立されました。20年間の運営を経て、現在では各种クーラーや電力収集リング装置、水処理装置、鉄道保守、オンライン監視、知能診断などの製品や、システムの研究開発、生産、サービスを提供しています。同社の製品は、発電所、鉄道、重化学工業など様々な分野で広く使用されています。

この企業は常にフィンファン熱交換器と科学的進歩を通じてコア競争力を強化してきました。年間の研究開発費は売上の5%を占めています。また、専門的で、優秀かつ革新的な実践的な研究開発人材を擁しており、エンジニアや技術者の割合は20%以上です。

フィンファン熱交換機は、顧客にワンストップソリューションおよび包括的な製品サービスを提供する立場にあります。售前の専門チームが設計支援やシステム協力サービスを顧客に提供します。売上には実際の技術的、管理的、生産的な人材がプロセスの管理、設置指導、技術研修、試運転、検査を行います。アフターサービスは、特別なアフターサービスで、品質問題分析、迅速な対応と現場で発生する品質問題の解決、そしてシステム設計に関する長期改善です。

著作権 © 上海リッチM&E製造株式会社。全著作権所有。 - プライバシーポリシー