これは、電力発生における同期コンデンサで水素クーラーを使用する場合、さらに役立ちます。うまくいけば、パフォーマンスが向上し、より長持ちし、メンテナンスも簡単になります。リッチ 水素冷却システム 多くの利点を提供し、複数の容量を制御してアプリケーションを健全に保つことができます。

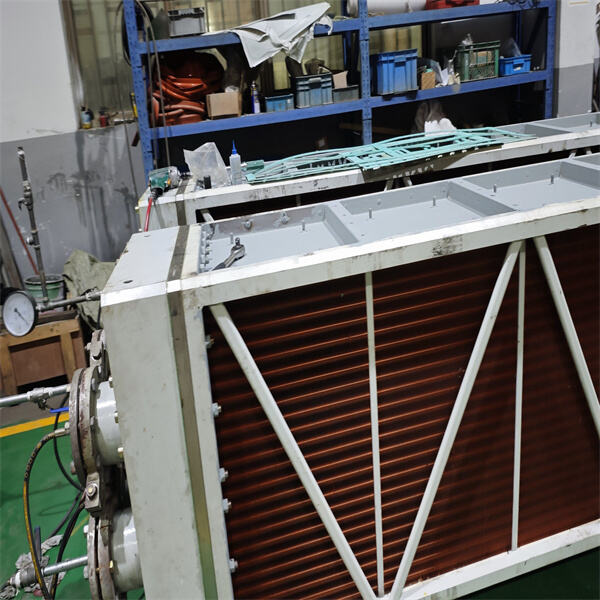

同期コンデンサは送電システムに追加のサポートを提供でき、水素クーラーはこのサポートの最高レベルを提供できます。まず第一に、彼らはキャパシタ以上に非常に優れた冷却性能を持っています。これは重要です因为她、なぜならいくつかのキャパシタは大量に加熱された場合、正しく動作しなくなるか、完全に動作を停止するからです。これが起こると、キャパシタが過熱し、非常に悪い結果が発生します。これが、彼らが安全に水素を絶縁材として捕らえ、その過程でほぼ絶対零度まで冷却する方法です。

次のものでは、水素冷却器がコンデンサ内に蓄積する湿度を低下させるのに役立ちます。空気にさらされるコイルの場合、過剰な熱や凝縮水が部品の錆を悪化させ、最終的に内部に湿気が発生することがあります。錆を取り除くのは非常に困難であり、構造的な損傷につながります。水素冷却器は湿気の上昇を防ぎ、コンデンサの寿命を延ばし、時間とともに運転効率を向上させます。

同期コンデンサーのほかに、SRから多くの年数を引き出すのに役立つもう一つの重要な部品は、多くの種類のエネルギーに対して重要な水素冷却装置です。水素冷却装置は、低温度と湿度を維持し、損傷が発生するのを防ぐために設置されています。これはさらに数年は持続するでしょうが、修理や交換が必要な場合は、長期保証での節約ではなく、私たちのポケットから費用がかかります。リッチ容量は時間とお金を節約するので非常に重要です。これほど良好に動作すれば、それは私たち全員にとってより長期間良いことです。

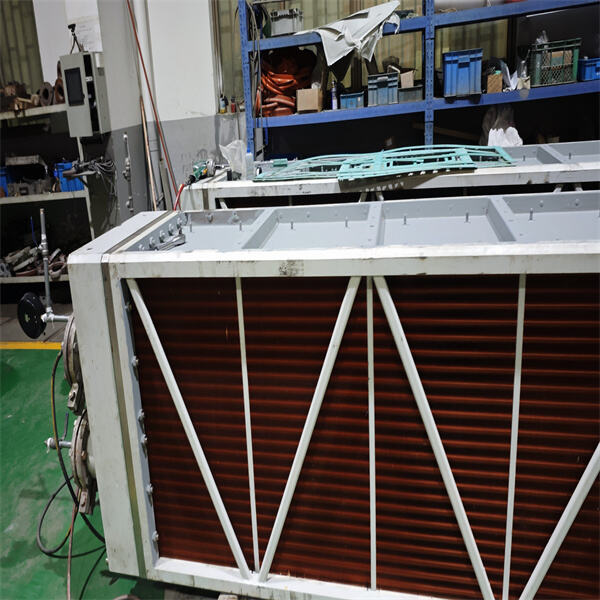

これらの部品の中には、この機器の運転を維持するために非常に重要な同期コンデンサ冷却システムが含まれています。コンデンサが過熱すると、その機能を完全に失うか、単に完全に故障する可能性があります。その強い影響により、コストだけでなく危険も伴う修理が必要になる場合があります。 発電機水素冷却システム は、この過熱を克服するための冷却システムによる完璧なデモンストレーションです。単純に言えば、コンデンサが無事である(そして過熱しない)ことを保つための予防策であり、寿命を延ばすことができます。逆に、すぐに終わりを迎えてしまう場合があります。コンデンサが過熱しないようにする冷却システムがあれば、エラーコンディションを回避できます。

同期コンデンサはさらに、定期メンテナンスのために水素クーラーが必要です。コンデンサの保守において非常に効果的で、損傷を防ぎます。予防は治療よりも長く続き、定期的なメンテナンスによって問題が大きな懸念になる前に防止できます。しっかりと管理された 発電機の水素冷却 は、何年にもわたる高性能を意味します。したがって、水素クーラーがあれば、同期コンデンサを稼働状態に保つのに十分です。

同社は常に顧客に対して、同期コンデンサ用の水素冷却装置に関する製品サービスのライフサイクル全体を通じて回答を提供しています。技術専門家のプロセールススタッフが顧客に設計と開発ソリューションおよびシステム協力ソリューションを提供します。営業チームには、高度なスキルを持つ技術者、マネージャー、生産人員が揃っており、プロセス制御、設置支援、技術支援、ならびに試運転と検査を行います。アフターサービスでは、アフター品質分析、現場の品質問題への迅速な対応と処理、そしてシステム設計に関する長期的な改善を行う専門チームが存在します。

同期コンデンサ用の水素冷却装置は、顧客にワンストップソリューションおよび包括的な製品サービスを提供する立場にあります。售前は技術専門家チームで構成されており、顧客に設計支援とシステム協力サービスを提供します。営業部門には技術的、管理的、生産的な人材が揃っており、プロセスの管理、設置指導、技術研修、試運転、検査を行います。アフターサービスは特別なサービスで、アフター品質問題分析、迅速な対応と現場で発生する品質問題の解決、そしてシステム設計に関する長期的な改善を行います。

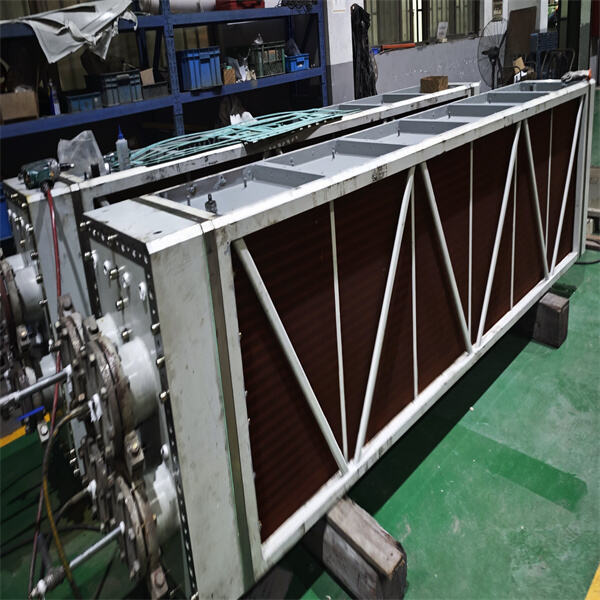

上海リッチM&E製造有限公司は1998年に設立され、同期コンデンサ用の水素冷却装置を製造しています。その後、冷却装置や電力収集リング、水処理システム、鉄道保守、インテリジェント診断、オンラインモニタリングなど、さまざまなシステムや製品の生産者になりました。

同社は常に技術的および科学的な革新を同期コンデンサ用の水素冷却装置に取り入れています。年間の研究開発費は売上の5%を占めており、専門的で質の高い創造的、革新的かつ実践的な研究開発チームも有しています。エンジニアや技術チームの割合は20%以上です。

著作権 © 上海リッチM&E製造株式会社。全著作権所有。 - プライバシーポリシー