The penetrating plate hydrogen cooler and air cooler is a high-efficiency cooling element which has been developed rapidly in recent years. Since the establishment of the company, we have successfully developed and manufactured 125MW double-water generator air cooler, air-cooled generator air cooler, 300MW, 600MW class water-hydrogen-cooled generator cooler, etc., and 1000MW class thermal and nuclear power water-hydrogen-cooled generator coolers, etc., which are widely used in generators, motors and other fields.

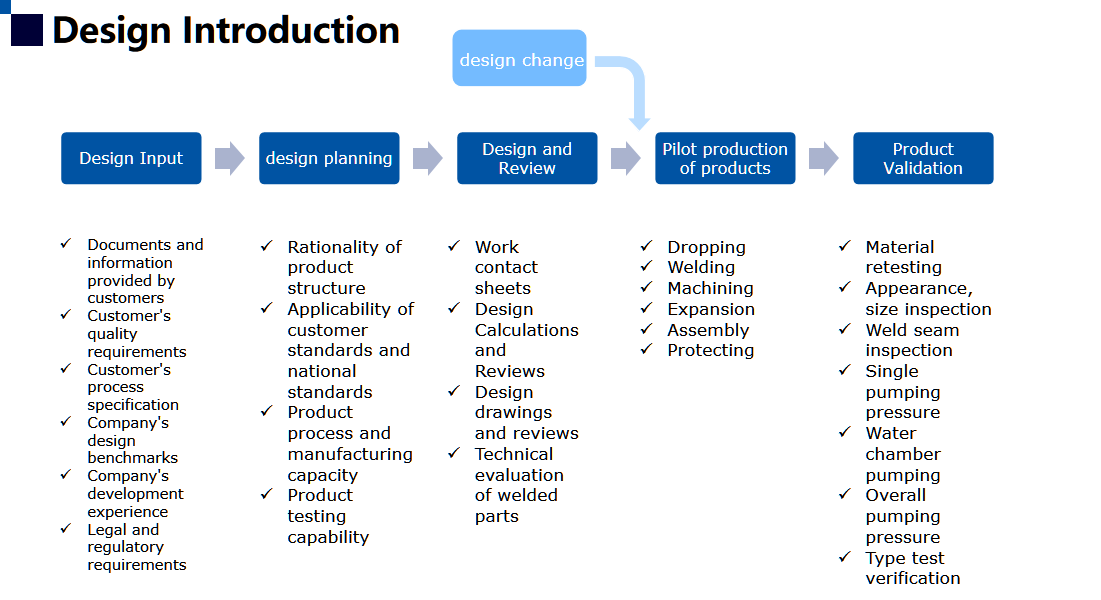

For the production design of the cooler, our company has a standardised process:

1.Design Calculation Process

We provide design calculations for coolers based on the following conditions:

①Heat transfer boundary conditions provided by the customer

②Material requirements for cooling tubes, heat sinks etc.

③The initial structure according to the interface and shape

④Different working conditions for on-site operation

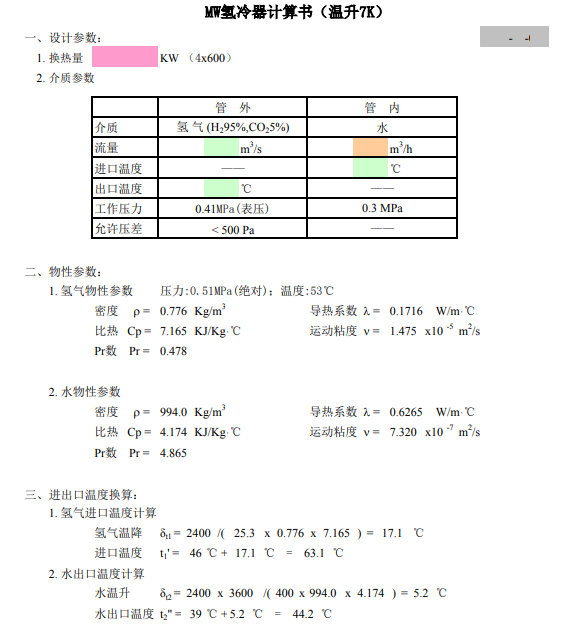

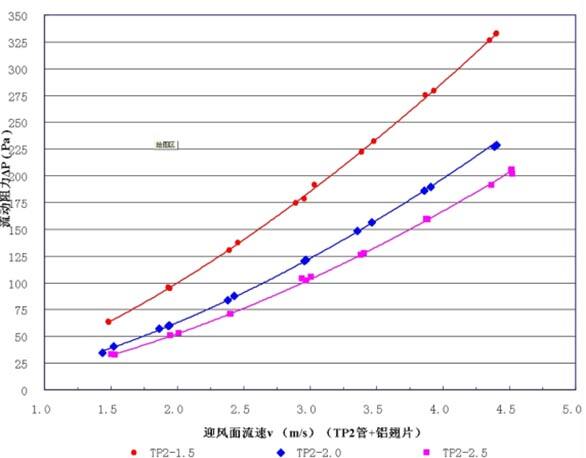

2.Hydrogen cooler calculator

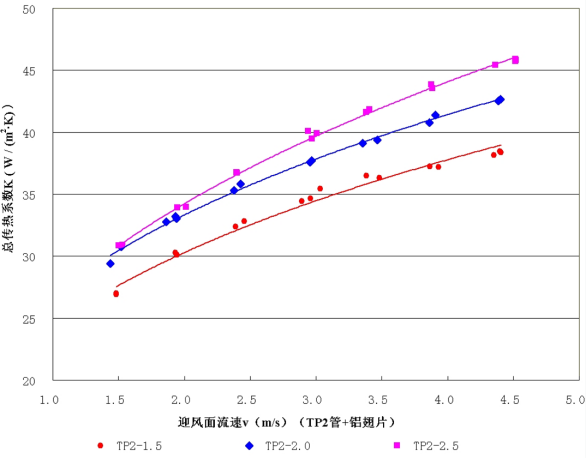

3.Heat transfer and resistance curves

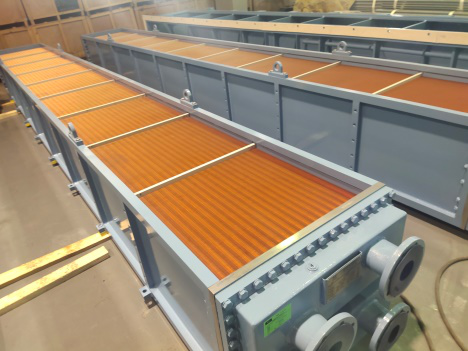

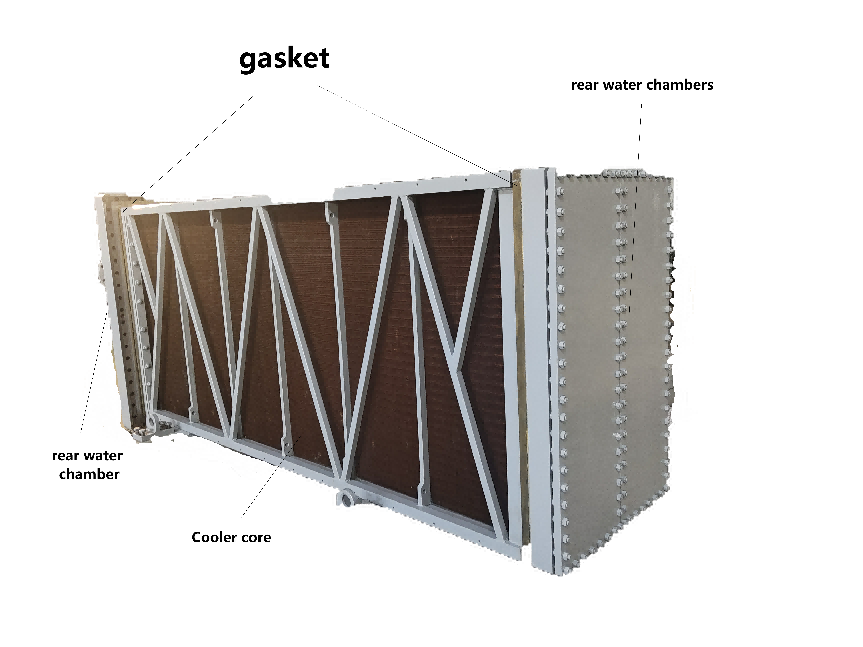

Product Structure:

Main parts: front water chamber, rear water chamber, cooler core, sealing gasket, etc.

①Front and rear water chambers: inlet and outlet flanges, internal ribs, drain and exhaust ports

②Cooler core: composed of front tube plate, rear tube plate, support plate, frame (or side plate), heat sink, heat exchanger tube, etc. Between the cooler frame (or side plate) and the rear tube plate, the telescopic sliding guide structure is adopted to eliminate the thermal expansion stress;

③Liner: to prevent leakage of the medium, the material varies according to the medium.

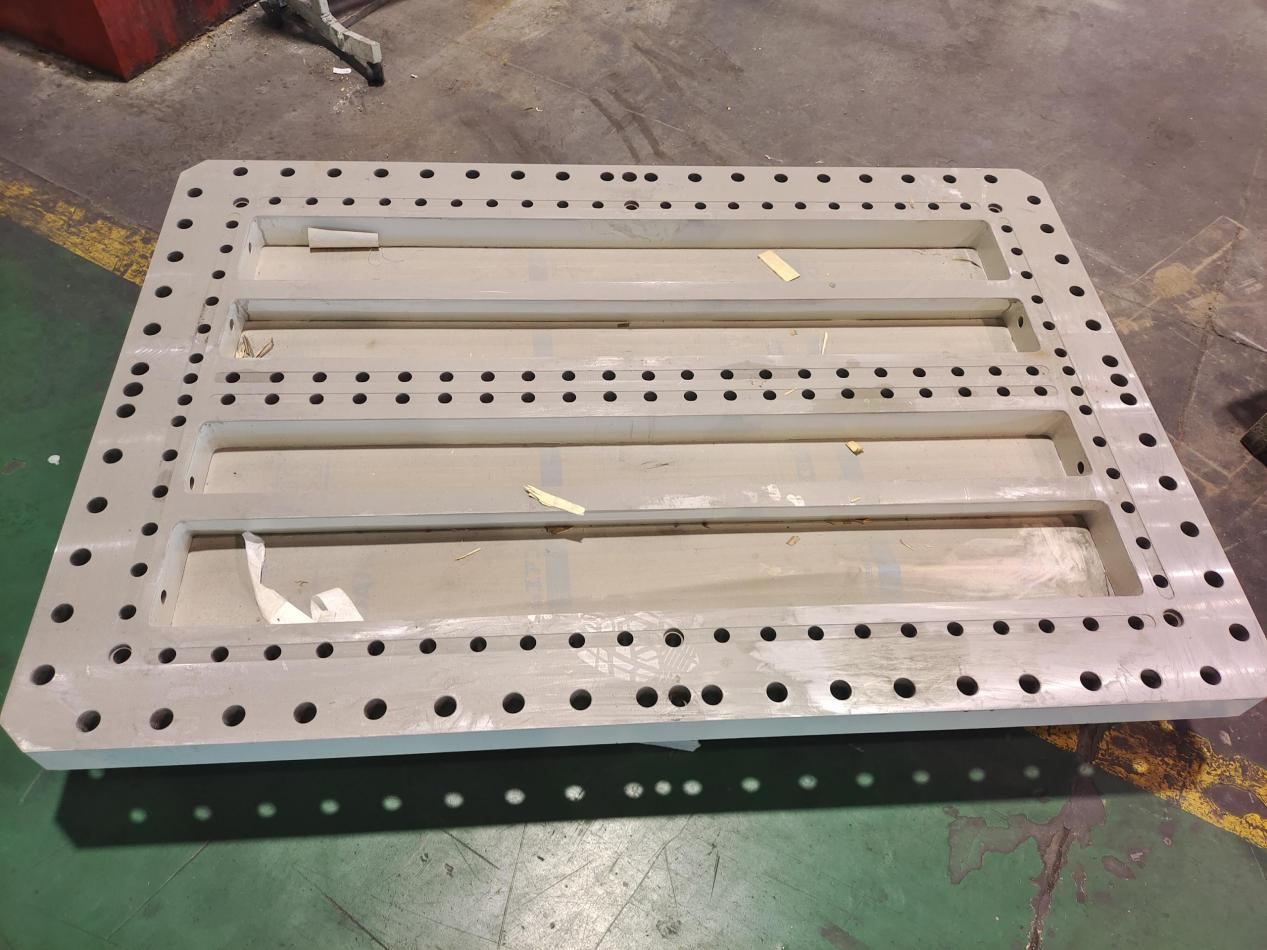

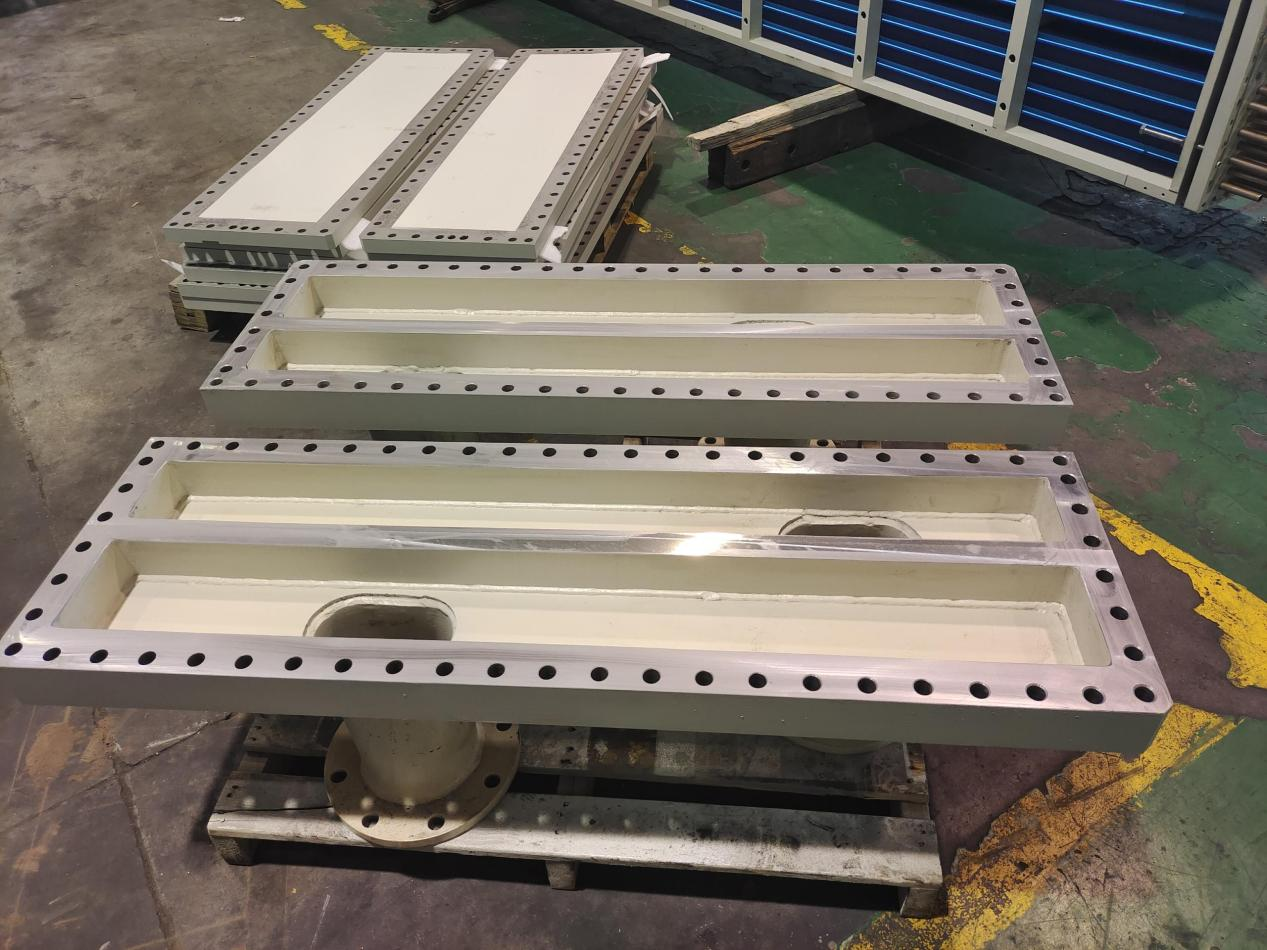

Front and rear water chambers:

①Welded construction

②Protective treatments such as rubber lining are available

4.Rear water chamber

5. Front water chamber

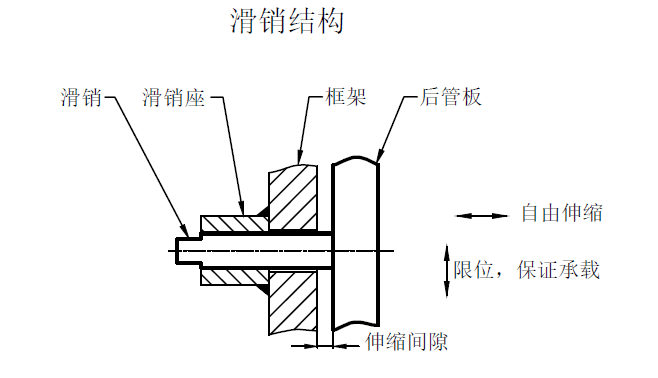

slide pin:

①Differences in expansion coefficients and temperatures of the cooling tubes and the cooler frame result in different expansion of the cooler core and frame.

②Slide pin structure ensures load bearing while allowing the cooler core to expand and contract freely.

6. Slide pin construction

Product Features:

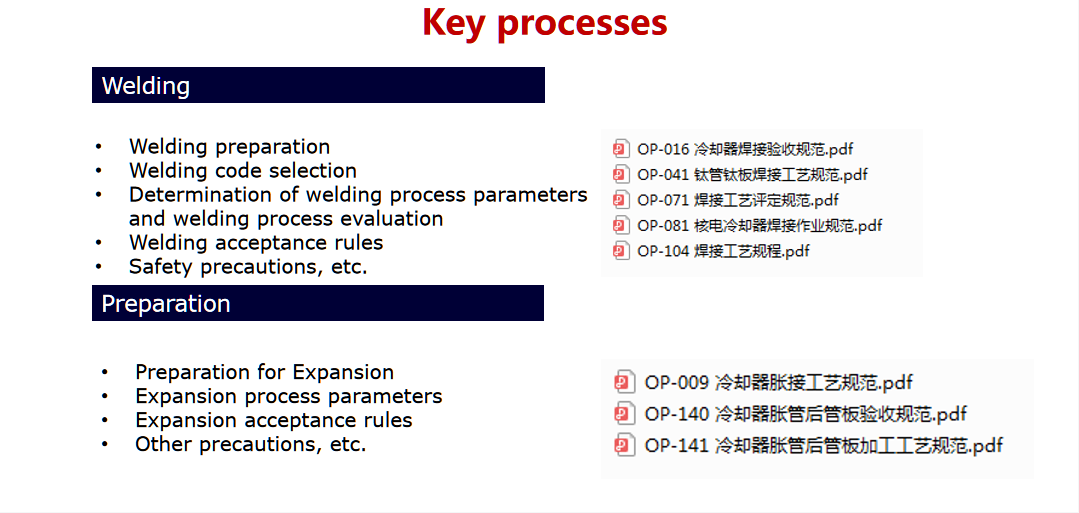

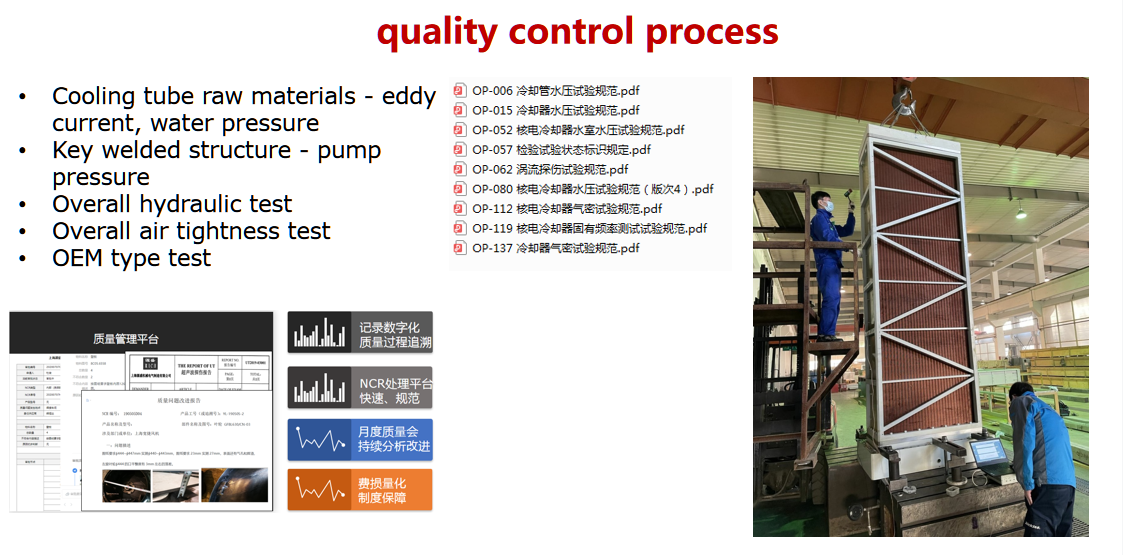

In the process of manufacturing and quality control of the cooler, our company has carried out strict process specification for each of its processes:

7. Key processes

Copyright © ShangHai Rich M & E Manufacturing Co., Ltd. All Rights Reserved - Privacy policy