Many machines we see everyday depends on plate and fin design. That encompasses automobiles of the car variety, flying contraptions in the form of planes and incredibly mundane items such as refrigerators. This design is a step ahead in also preventing the system from overheating and thus ensures smooth and efficient operation of all sectors simultaneously. In this post, we will take a detailed look at the plate and fin heat exchangers which includes its advantages, construction method, applications and tube bundle (shell) design as opposed to other types of heat exchangers and how to make it long-lasting. Rich fin and plate heat exchanger Heat ExchangerThe Plate and fin heat exchangers provide great characteristics which make it advantageous. One of their biggest advantages is how good they are at keeping things cool. The fins and plates of the unique design create a large amount of surface area for the coolant—either liquid or gas—to make contact with. The wide surface area allows the coolant to deposit heat from within the engine on to the plates and fins, where it is then dissipated in to the air passing through it. A feature of this design, which can be particularly useful for certain applications, is that it is small and space saving. Thus plate and king warm exchangers capacity ample in certain bound or tight amplitude place added structure ability not match.

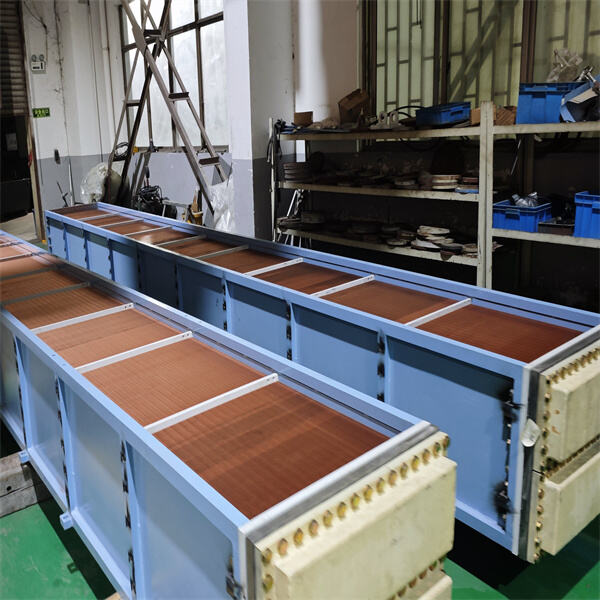

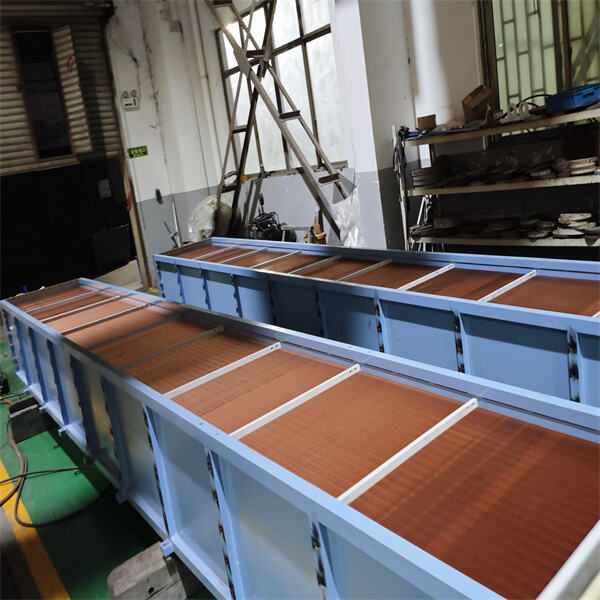

Stacking Plates and Fins in Plate and Fin Radiators The plates are flat and thin, the fins long and thing. Its plates and fins are arranged in such a way as to create channels for fluid flow through. One of these is air or a liquid. The plates and fins are what the fluid interacts with as it passes through these channels. The heat is absorbed from the fluid by the plate and fin, which in turn disperses this heat to other externa environment. This technology is ubiquitous and plays a key role in the majority of applications. Car radiators are a popular location for this technology. Leadership: Engine Cooling Liquid (Cars) The liquid coolant flows to the radiator and when it passes through the plates and fins, This is how the coolant gets hot, and it in turn heats up the plates/ fins that allows it to dump heat out in the air outside.

Refrigerators which are termed the other significant application of plate and fin technology. In a typical fridge, the inside gets cool simply because of gas coolant. The gas becomes hot when it is compressed. Air passes over a series of Rich plate and fin heat exchanger where it absorbs the heat from the hot gas. Once it moves away, the gas cools down and then goes back into the fridge to repeat the process; keeping our food cold.

Heat exchangers come in a multitude of designs that all serve more or less the same purpose. Tube and Fin Design One of the most common alternatives Tubes hold the fluid in this design; fins are attached to the exterior of these tubes. Although this tube fin design works good but not as efficient as plate and fin. The issue for this is because the tube and fin layout has lesser of a surface area for the fluid to be in connection with, generating that cooling is not mainly as fast or green.

Plate and fin cooling systems are beneficial in maintaining temperature, performance and functionality of several machines but proper maintenance is necessary to make the same water workable for longer period. One of the most important things is to ensure that the fins are clean and clear from dirt and debris. You can only do this by either running water through the fins or using a compressed air blower to blow them out if there is any dust or dirt built-up. Similarly, another important one is the replacement of the coolant at timely intervals. This Rich Plate fin heat exchanger prevents the coolant from accumulating contaminants as it might otherwise lose its efficiency and capability over a certain period of time.

ShangHai Rich M and E Manufacturing Co., Ltd. was established in 1998. After twenty years of operations, it has Plate and fin of all sorts of coolers and power collections ring devices waters treatment devices railway maintenance online monitoring, intelligent diagnosis and other products as well as research and developments for systems, productions and service as parts of the company The company's products are extensively employed in power stations railroads heavy industry, as well as other fields.

Sales has Plate and fin technical, management and production workers to deliver procedure control and technical guidance installation for commissioning plus inspection. After-sales services have a separate responsible team for after-sales problem analysis, rapid reaction and solution of issues on-site in addition to long-term enhancements to the system design.

The company is always investing in technological and scientific innovations to Plate and fin. The annual research and developments expenses account for five percent of sales. In additions the company has an experienced groups of steady, practical and creative highly skilled researchers and developments experts and the percentages of engineering and technical personnel is greater than 20%.

Plate and fin has expert technical technicians, production and management staff for process control and guidance that is technical installation in commissioning, inspection and maintenance. After-sales services have a passionate team this is certainly responsible for issues that arise after sales, fast response and treatment issues that is on-site long-term improvements of product system design.

Copyright © ShangHai Rich M & E Manufacturing Co., Ltd. All Rights Reserved - Privacy policy