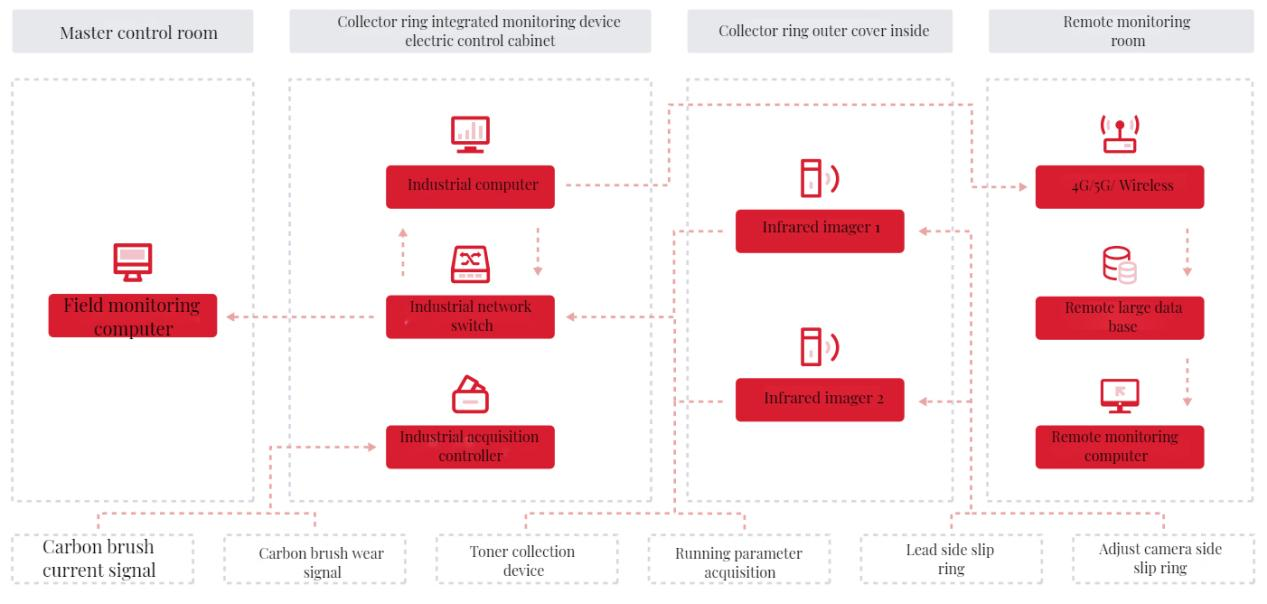

The integrated collector ring monitoring device replaces the relatively traditional means of collector ring monitoring in various power plants at home and abroad, and changes the shortcomings of manual periodic intermittent measurement. It meets the requirements of real-time, online, continuous monitoring and realises early warning of faults and timely treatment and elimination of safety hazards. It meets the requirements of real-time, online and continuous monitoring, realises early warning of faults, and deals with and removes potential safety hazards in a timely manner. At the same time, through the long-term monitoring of the temperature of the contact surface of the sliding ring and carbon brush, through the analysis of a large amount of data, to develop a set of By analysing a large amount of data, a set of critical value evaluation standards for different models can be formulated, which will provide powerful support for the subsequent design of new products and improvement of service products.

Hardware Introduction:

①Slip Ring Temperature Monitoring Module

Transmission of data to industrial network switches machine to display the temperature measurement image, monitor the temperature temperature measurement, query temperature history data curve, temperature alarm record and remote send temperature data to DCS and other functions.

②Carbon brush wear monitoring module

By means of electrostatic fields, filters, wind pressure transmitter, sensor module and high pressure generator remote monitoring module to an industrial network switch for data transmission and monitoring. The data is transmitted to an industrial network switch for data transmission and monitoring.

③Toner Collection Monitoring Module

The data is transmitted to the industrial network switch via Hall current sensors for data transmission and monitoring. to the industrial network switch to display the carbon brush current and query the current. display the carbon brush current, query the current alarm record and remotely send the current data to DCS. data to DCS.

④Carbon Brush Current Monitoring Module

Data is transmitted via Hall current sensors Transmission of data to the industrial network switch display carbon brush current, query current alarm record and remotely send current data to DCS.

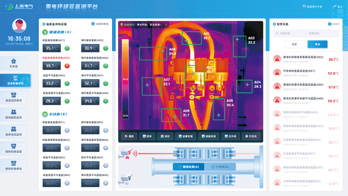

Software Introduction

The software development version can be customised according to the customer's requirements, is an industrial control soft configuration parts, on the Windows XP, Win7, Win8, Win10 operating systems have good compatibility, can be in 32-bit, 64-bit operating systems in stable operation, has a powerful configuration functions and data transmission functions, and has a powerful configuration function and data transmission function. It can run stably in 32-bit and 64-bit operating systems, and has powerful configuration functions and data transmission functions. It has powerful configuration function and data transmission function, which can meet the application and development of various monitoring methods and control functions of the monitoring system.

Functional Support:

①Support third-party interface code, can accept application software SDK development kit for various sensors.

②Support real-time and historical data curve recording and storage functions.

③Support a variety of remote communication functions, such as Modbus TCP/IP, Modbus RTU/DTU and other standard data communication protocols, suitable for industrial Large data collection.

④Support Web/Internet remote configuration function, increase the corresponding software Expansion packages, mobile phones, tablet PCs and other mobile customer terminals can achieve remote Data monitoring function of mobile phones, tablet PCs, etc.

⑤Support all kinds of hardware bus module driver function, provide support for data acquisition hardware module. module for data acquisition.

Copyright © ShangHai Rich M & E Manufacturing Co., Ltd. All Rights Reserved - Privacy policy