Conductive Slip Ring: Electrical Innovation for Safe and Efficient Power Transmissions

Introduction

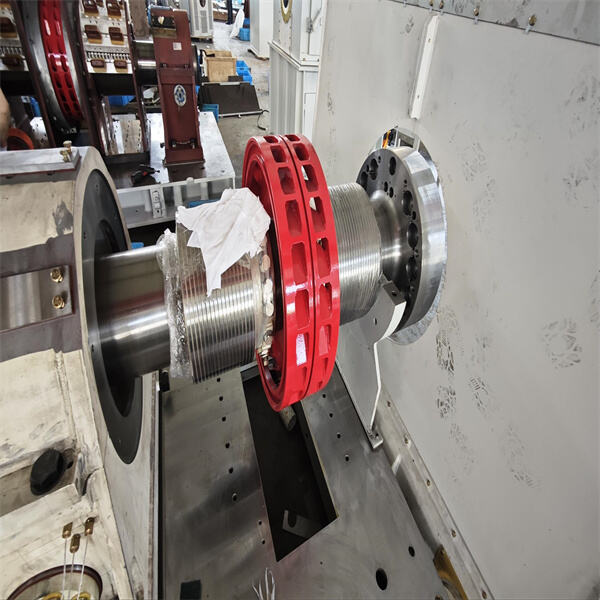

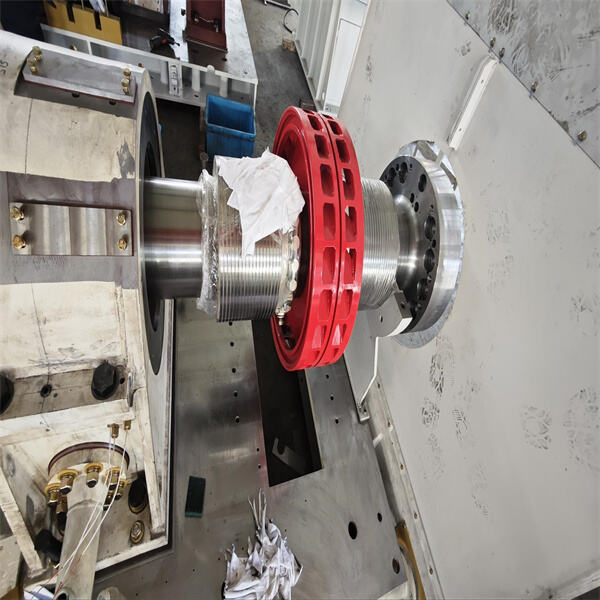

Have you ever wondered how electricity is transmitted between rotating and static components in mechanical systems? A conductive slip ring by Rich is a clever invention that solves this problem. It is an electrical connector that allows power, signals, and data to be transmitted between stationary and rotating parts without tangling wires or cables. We will delve into the various advantages of conductive slip rings, their innovative features, and how they can be used safely and efficiently.

Conductive slip rings have several advantages over other types of electrical connectors, such as brushes and springs. One of the main advantages is their ability to transmit power and signals without generating noise or interference. This is due to their use of low-resistance conductive materials, such as gold, silver, or copper. Moreover, conductive slip rings are less prone to wear and tear, as they have a low friction coefficient and self-lubricating properties that reduce the need for maintenance and repairs.

Another advantage of conductive slip rings as well as Rich slip rings on a generator is their high capacity to transmit power and signals. They can handle voltages ranging from a few volts to several kilovolts, and currents ranging from milliamperes to hundreds of amperes. This makes them suitable for a wide range of applications, from small household appliances to large industrial machines. Additionally, conductive slip rings can transmit various types of signals, such as digital, analog, and video signals, with high accuracy and low distortion.

Conductive slip rings have been around for over a century, but recent innovations have improved their performance and functionality. One of the most notable innovations is the use of fiber optic technology in slip ring designs. This allows faster and more secure transmission of data and video signals, without interference or distortion. Additionally, some conductive slip rings have integrated wireless communication modules, which enable remote monitoring and control of rotating machinery.

Another innovation in conductive slip rings is the development of modular designs of Rich and quick-change features. This allows the slip rings to be easily replaced or upgraded, without the need for extensive disassembly or downtime. Moreover, some conductive slip rings have advanced sealing and cooling mechanisms that enhance their durability and reliability in harsh environments.

Safety is a crucial consideration when using conductive slip rings or the Rich high power slip ring, as they are part of electrical systems that can pose risks of shocks, burns, or explosions. It is important to comply with safety standards and regulations, such as those set by the National Electrical Code (NEC) and the International Electrotechnical Commission (IEC). Here are some guidelines on how to use conductive slip rings safely and effectively:

- Choose the right type of slip ring for your application, based on voltage, current, frequency, and signal requirements.

- Ensure that the slip ring is installed properly, with adequate clearances and grounding.

- Check that the slip ring and its connections are free of debris, corrosion, or damage before use.

- Avoid touching or working on the slip ring while it is energized or rotating.

- Use appropriate personal protective equipment, such as insulated gloves and goggles, when handling or testing the slip ring.

- Monitor the slip ring's performance, such as temperature, vibration, and noise levels, regularly to detect any anomalies or malfunctions.

Conductive slip rings are critical components of electrical systems, and their failure or malfunction of Rich rotary slip ring can have serious consequences for safety, productivity, and costs. Therefore, it is important to choose high-designed quality conductive slip rings, manufactured, and tested according to rigorous standards and specifications. Here are some factors to consider when selecting a supplier or manufacturer of conductive slip rings:

- Reputation and experience in the industry, with a track record of providing reliable and customized solutions.

- Expertise and resources in design, engineering, and testing of slip rings for various applications and industries.

- Compliance with international and local standards and regulations, such as ISO 9001, CE, and RoHS.

- Support and service, such as technical assistance, troubleshooting, and warranty for their products.

- Continuous improvement and innovation in the design, materials, and technology of their slip rings.

conductive slip ring is staffed by experienced technical professionals, production and management staff for process control and guidance this really is certainly technical installation because well as commissioning plus inspection. After-sales service has a separate team that is in control of post-sales analysis of problems, speedy intervention and resolution of dilemmas on site too as long-term enhancements towards the system design.

ShangHai Rich M and E Manufacturing Co., Ltd. was established in 1998, is a conductive slip ring. After that, it has become a producers of a ranges of items, including coolers and power collections rings, water treatments systems, railway maintenance, intelligent diagnosis, online monitoring, and other systems and products.

The conductive slip ring always provides customers and a single-stop solution for all-inclusive product, pre-sales professional team of specialists in technical areas to give you customers with design services and system cooperation service; Sales has an expert professionals, managers and production workers who provide procedure control, installation guidance and technical training, aswell as commissioning and inspection. After-sales services include a group that try specific quality problem analysis rapid response and quality of quality problems that arise on-site, and long-term improvement regarding the system design.

The company is always using technological and scientific innovations to conductive slip ring. The annual research and developments costs account for 5percent of sales. The company has also a teams of professional, top-quality creative, innovative and practical researchers and developers. The percentages of engineers and technical teams is greater than 20 percent.

Copyright © ShangHai Rich M & E Manufacturing Co., Ltd. All Rights Reserved - Privacy policy